When it involves running any business handling products, whether it's eCommerce, retail, or wholesale, managing inventory efficiently becomes the prime concern. Especially if you own a small-sized business, issues arising thanks to inventory theft or human errors would never allow you to make a profit and grow your business. to make sure flawless & smooth stock management & order fulfilment processes in your small retail business, you must possess a sensible barcoding system. A Barcoding inventory system can assist you in making your process of monitoring, managing, and securing your inventory accurate and quick.

Here, during this article, we've included comprehensive information about barcodes and barcoding inventory systems so that you'll deploy the simplest one helping you to sustain and grow your small-sized business exponentially.

What Is Barcode?

Barcode includes a machine-readable code consisting of parallel lines of various width and variety assigned to a specific commodity. The barcode encodes information during a visual pattern that a machine can read and convert into the user's language. A barcode contains information about the merchandise like its price, weight, manufacturing & expiry date, name of the manufacturer, make, model, location, etc.

Almost everyone has seen barcode labels printed on the merchandise packages within the supermarket. As soon as you buy a product from the shop, the cashier scans the barcode label thereon, and therefore the entire information that product gets displayed on the system. The invoice gets printed, and consequently, the products purchased by the customer are automatically deducted from the inventory threshold.

How Does the Barcoding System Work?

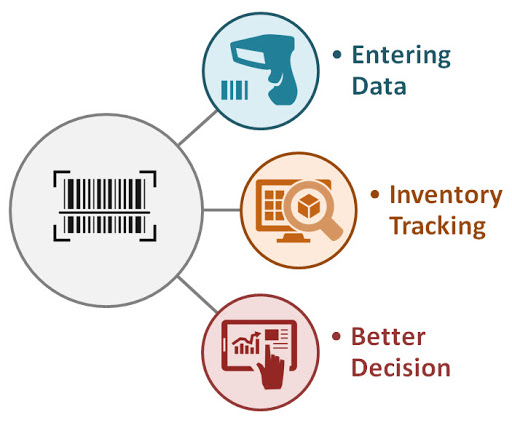

The barcode differentiates one item from another during a store, making it easy for the shop managers to manage the inventory, sales, and order fulfilment.

When a product is placed during a warehouse or a stockroom, the worker scans the merchandise's barcode. Then, the barcode inventory system records the entry of the merchandise at a specific location. When that product is sold, it's again scanned by the barcode scanner to enter the small print and price of the merchandise within the customer invoice. The number of that product sold is automatically updated within the inventory system.

The barcoding system ensures that the correct information about the merchandise has been recorded within the invoice and accurate inventory management has been performed. The whole sales and order fulfilment process is flawless & quick, and therefore the customer experiences a superb shopping experience at an equivalent time.

Barcodes cannot work without implementing the proper barcoding inventory management system. So, let's dive into the complete information about barcoding inventory management systems that might help you choose the proper one for your business.

What Is the Barcoding Inventory System?

A barcoding inventory system includes hardware like barcode scanners & printers and a listing management software that runs on desktops and mobile devices.

The barcoding inventory software allows you to automate the method of making barcode labels.

The barcodes are printed with the assistance of specialized barcode printers. Those labels are manually pasted on the items.

While purchasing and selling the products, the barcode scanners can scan the barcodes on the products to record and monitor the inventory accurately. Below mentioned are some popular scanners included in barcoding inventory systems lately.

Laser Scanner - Laser Scanner is one of the foremost popular sorts of barcode scanner. It uses laser technology to read black and white spaces in a barcode.

Linear Imagers - The linear imager barcode scanners can read-only 1D barcodes by capturing the barcode's picture and analyzing the image's knowledge.

2D Area Imager - 2D area imagers are almost like linear imagers, except that they need the power to read 2D and stacked barcodes. Moreover, this sort of barcode scanner can read barcodes in any direction.

Many inventory management systems integrate barcode apps that employment on smartphones. In therein case, you do not need to include a barcode scanner separately. You'll directly scan the barcodes using Smartphones with barcoding apps.

The barcoding system is beneficial for accurate stock management and control. Moreover, you'll accelerate the speed of the method of receiving and shipping goods. It gives you the correct information about the things present within the warehouse and the sold people. By printing and scanning barcodes, you'll track everything that enters your warehouse and leave your warehouse. The barcode inventory system plays a severe role in preventing the issues you always face thanks to the wrong inventory count, like out-of-stock conditions and lost sales.

Essential Components of a Barcoding Inventory Software?

Below are a few essential components of a barcoding system that can help you streamline your entire supply chain process.

Inventory Management Software

The inventory management software includes the features that allow you to import product lists from excel or the other application, create barcode labels, and print them. Besides designing and printing barcodes, it also can -

- Update inventory calculates on a real-time basis.

- Track inventory across multiple warehouses

- Handle order management

- Integrate with your accounting

Barcode Printers

The barcode printers connecting with your | and your"> together with your desktop or laptop loaded with your inventory management software are wont to print the barcodes. The printed labels are then pasted on the packaging of every item for his or her unique identification.

Barcode Scanners

The barcode scanners are wont to scan the barcode on the item packaging while entering or leaving the warehouse to stay track of the inventory count. There are some barcode scanners available which include -

- Handheld scanners are the foremost commonly used barcode scanners available in corded and cordless (wireless) styles. The handheld scanners work with computers to record the knowledge about the incoming and outgoing inventory.

- On-Counter Scanners are installed on the cash counters and are bioptic plane instruments that will capture any printed 1D or 2D barcodes with high-end speed.

- Mobile Scanners include the functionality of a PC and a barcode scanner both. One among the most superficial samples of portable scanners maybe a Tablet which will be wont to scan the barcodes and record the inventory's movements.

- Presentation Scanner also referred to as In-Counter Scanner, is employed when multiple items must be scanned at an equivalent time.

- Fixed-mounted Scanner includes sensors that will read barcodes of the things passing ahead of it. It's also referred to as a hands-free barcode scanner that permits convenient and high-speed scanning.

- Wearable Scanners are devices worn on an arm, hand, or finger using sensors to scan the barcodes.

How To found out A Barcoding System?

With the assistance of a computer loaded with inventory management software and paired with a barcode scanner, you'll found out your barcoding system. Further, you would like to follow the below-mentioned steps -

Step 1: Generating Barcodes

The first thing you would like is barcodes. Without feeding product information into your inventory management system, you can't generate barcodes. So, you would like to import a spreadsheet with the merchandise information in your inventory management system. If you do not have your product information database, you'll manually enter it into your inventory management system. The system then generates barcodes for every product supported its details like size, colour, brand, etc. Using the barcode printer, you'll then print those generated barcode labels.

Step 2: Labelling the Inventory

Now once you have barcode labels available, you would like to physically paste them on each item you've got in your warehouse for his or her unique identification. This step is that the most time-consuming one and requires a substantial amount of human effort. But, once it's done, you've got clear visibility of the number of every product item available in your multiple warehouses. The knowledge on the system aligns with the particular stock, and thus all the issues concerning missing items, overselling, and lost sales get solved.

Step 3: Scanning Barcodes

The end step is to scan the barcodes of all products available in store so that the software has a correct record of the stock available. Suppose you do not scan the item's barcode while purchasing or selling it. In that case, your system won't show accurate inventory count leading to tons of accounting errors and mismanagement issues within the business.

How Barcoding Inventory System Increase Your Stock Accuracy?

The barcoding inventory system can increase your stock accuracy by -

Providing Access To The Accurate Inventory Information

When you receive products, you'll print and scan the barcodes with accurate information using the barcoding system. After selling the items, the software automatically removes the already sold items from the stock. Thus, you'll make confident that you have access to accurate inventory information in your system.

Creating Purchase and Sales Orders

Your barcoding =system can create purchase & sales orders. To ensure accuracy while receiving the charges, you'll verify the barcodes with the acquisition orders. While selling, the things are often picked and packed easily from the barcode information mentioned within the sales orders. Following this process, you'll make particular about shipping the proper products to your customers.

Integrating With the web Store

Your barcoding inventory management system integrated with your online store ensures that product quantities are accurately mentioned in your online store. Because the barcoding inventory management system is aligned with the particular stock within the warehouse, there aren't any instances of overselling and disappointing the purchasers by cancelling the orders for the things that are not available within the store.

Helping In Right deciding

The barcoding inventory system notifies you if your products' quantity goes below a specific threshold. This helps you choose on placing the orders together with your suppliers at the proper time. Moreover, the barcoding inventory system provides you with accurate information about the stock available in several warehouses. So, once you receive the order for a specific item, you recognize which warehouse must be contacted to ship it, thus creating the proper shipping decisions quickly and supplying fantastic shopping experiences to the purchasers.

0 Comments